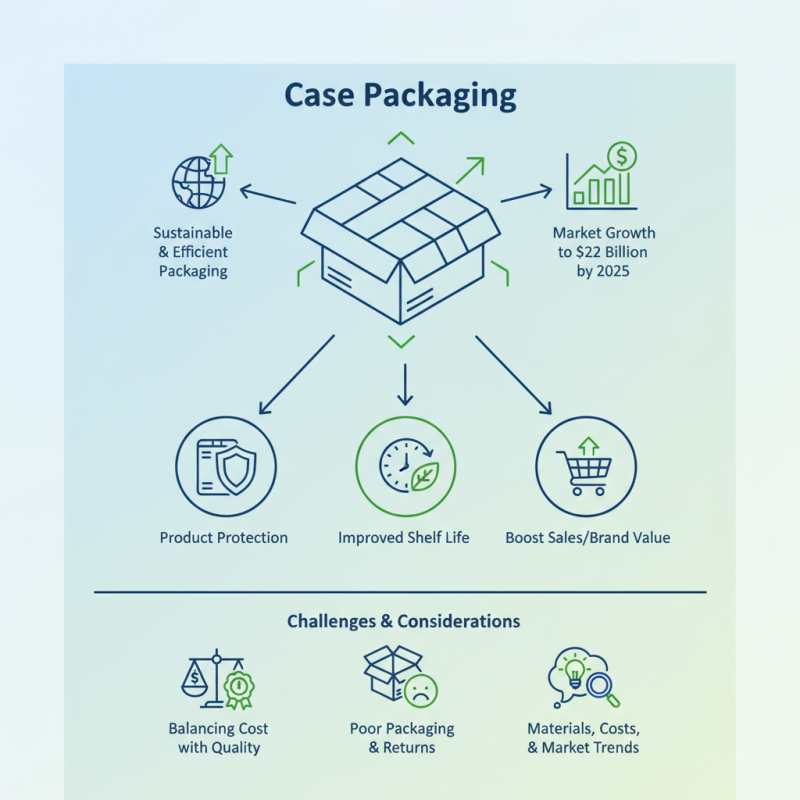

Choosing the right case packaging for your products is crucial in today’s competitive market. According to a recent report by Smithers, the global case packaging market is expected to reach $22 billion by 2025. This growth is driven by increasing demand for sustainable and efficient packaging solutions. Effective case packaging can enhance product protection, improve shelf life, and even boost sales.

Expert in the field, Dr. Emily Carter, emphasizes, "Case packaging is not just about protecting products; it’s about enhancing brand value." This highlights the need for businesses to focus on more than just functionality. Companies often face challenges, such as balancing cost with quality. Many underestimate how poor packaging can affect customer perception and lead to higher return rates.

In essence, selecting the right case packaging involves careful consideration of materials, costs, and market trends. There is a notable gap between what brands intend and the packaging solutions they implement. This reflection is vital; understanding the dynamics of case packaging can ultimately determine the success of a product in the marketplace.

Selecting the right case packaging materials is crucial for product safety and brand perception. According to a report by Smithers Pira, over 70% of consumers form their purchase decisions based on packaging visibility. This highlights the need for effective design and material choice.

Durability is a key factor. Materials like corrugated fiberboard and rigid boxes offer protection during transit. However, costs can escalate. A balance must be struck between quality and budget. Reports indicate that companies can save 15-30% by optimizing packaging designs without sacrificing integrity.

Environmental considerations are increasingly important. Many consumers prefer sustainable options. A survey by Nielsen found that 66% of global consumers are willing to pay more for eco-friendly packaging. Choosing biodegradable or recyclable materials can enhance a brand's image. Yet, finding the right sustainable option can be complex and requires careful thought. It's essential to assess the trade-offs between cost, functionality, and environmental impact.

| Factor | Description | Material Options | Cost Range |

|---|---|---|---|

| Product Type | Consider the nature of the product being packaged (fragile, perishable, etc.). | Cardboard, Plastic, Foam | $0.10 - $5.00 per unit |

| Durability | How well the packaging withstands handling and environmental conditions. | Corrugated Boxes, PET, Glass | $0.20 - $10.00 per unit |

| Sustainability | Consider eco-friendly materials and processes. | Recycled Paper, Biodegradable Plastics | $0.15 - $3.00 per unit |

| Regulatory Compliance | Ensure the packaging meets safety and regulatory standards for your industry. | FDA Approved Materials, Food-Safe Plastics | $0.30 - $12.00 per unit |

| Branding | Utilize packaging to enhance brand image and visibility. | Custom Printed Boxes, Laminated Labels | $0.50 - $7.00 per unit |

When selecting case packaging solutions, it's essential to understand the various types available. Each type serves a specific purpose and can affect both product presentation and protection. For example, corrugated boxes are common for shipping fragile items. They provide excellent cushioning and are easy to stack. However, they can be bulky and might not fit well in smaller spaces.

Another option is shrink wrap, which is often used for bundling products. This approach is cost-effective and offers a clear view of the product. Yet, it lacks structural support and may not prevent damage during transit. Rigid containers, on the other hand, offer superior protection yet can be more expensive and harder to recycle.

Choosing the right type requires careful consideration. Analyze your products and their needs. Don’t rush the decision-making process. Evaluate how each packaging type aligns with your goals. Reflect on sustainability. Eco-friendly options are increasingly popular. But do they meet your performance standards? Balancing cost, sustainability, and protection is crucial for effective packaging strategy.

When selecting packaging, product protection and safety are paramount. The right case packaging shields products from damage during transit and storage. A study by the Packaging Institute found that 30% of products are damaged before reaching the customer. This statistic highlights how crucial robust packaging is to maintain product integrity.

Consider the materials you choose. Corrugated cardboard, for example, is known for its strength. It provides excellent resistance against impacts and helps prevent breakage. According to a report by Research and Markets, the global demand for eco-friendly packaging is expected to grow by 5.5% annually. This trend suggests that businesses should adapt to evolving consumer preferences while ensuring safety.

It’s essential to balance sustainability with protection. Some biodegradable materials may not offer the same level of durability. A company might choose a greener option but risk damaging their products. This dilemma poses questions about responsibility and efficiency. Finding a packaging solution that offers both protection and eco-friendliness is not straightforward.

When considering packaging options, sustainability is a key factor. Many materials contribute to environmental harm. Traditional plastic, for example, takes centuries to decompose. In contrast, biodegradable options offer a more eco-friendly path. They break down faster and reduce landfill waste. However, not all biodegradable materials are created equal. Some still leave harmful residues.

Recyclability is another important aspect. Using materials that can be easily recycled is crucial for reducing impact. Cardboard and certain plastics can be recycled but require proper systems to work effectively. Unfortunately, many areas lack access to these systems. This creates a disconnect between intentions and outcomes. Companies need to assess local recycling capabilities before making choices.

An effective packaging solution balances cost, sustainability, and function. Finding the right mix can be challenging. Customers are increasingly aware of environmental implications. They often prefer brands that prioritize sustainability. Yet, many packaging choices still lean toward convenience over care for the planet. A thoughtful approach is vital in making a positive impact.

Choosing the right case packaging goes beyond aesthetics. Cost is a significant factor that can make or break your budget. Start by assessing the materials used. Some packaging materials are expensive, while others offer similar benefits at a lower cost. For example, corrugated cardboard might be more cost-effective compared to custom plastic containers.

Tips: Consider the shipping cost. Heavier packages can increase shipping fees. Light-weight materials can save money. Don't forget about bulk purchasing. Buying in larger quantities can lower your overall packaging costs.

Also, consider the design. Complex designs may increase initial costs. Simplifying can lead to savings, but be careful. Complexity might convey quality in some cases. Evaluate if the aesthetic aligns with your product's image and customer expectations.

Lastly, analyze long-term costs versus short-term savings. Cheaper materials might wear out quickly, requiring more frequent replacements. This could lead to higher expenses down the line. Always weigh your options carefully.